PRODUCTS & TECHNOLOGIES

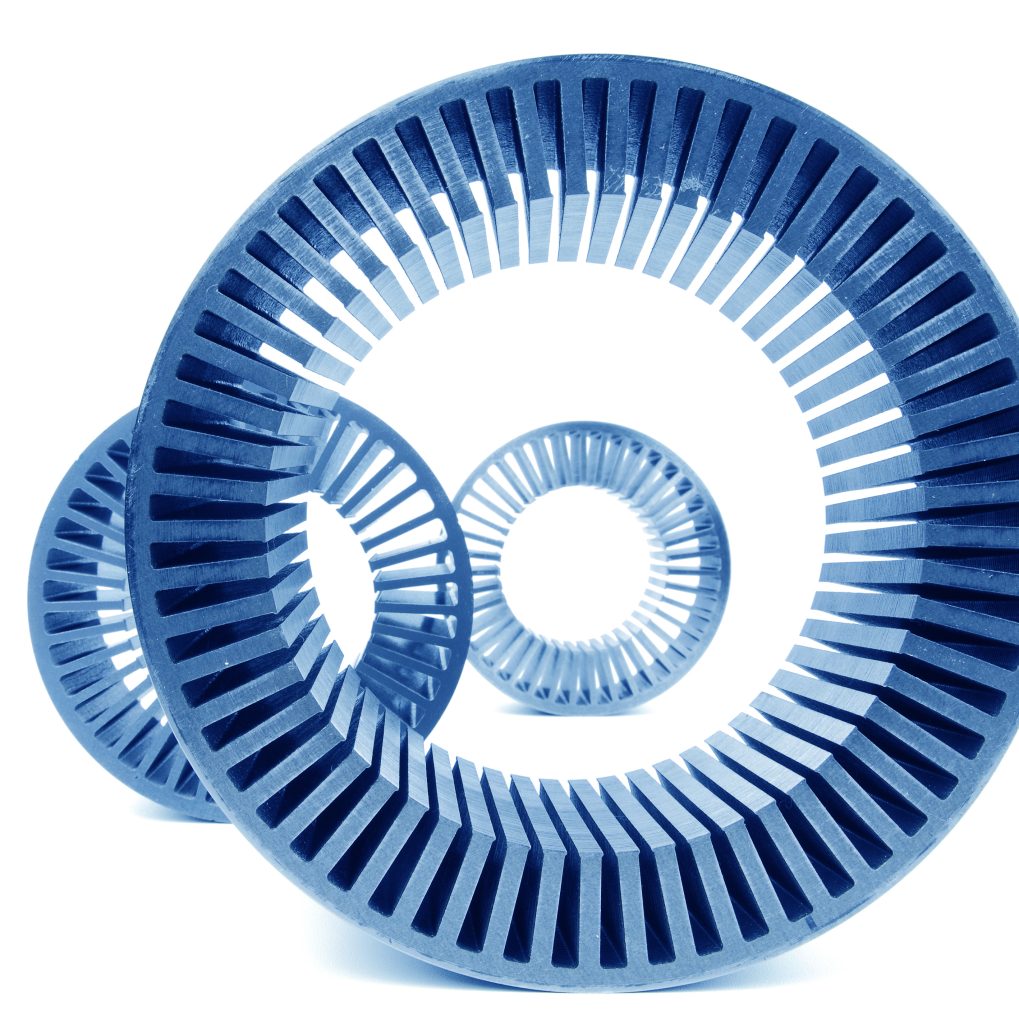

Our stator and rotor laminations are used in motors and generators in the industry sector such as energy, transportation, machinery & plant engineering, railway industry and electrical industry. They are manufactured using the following processes:

- progressive cutting for small diameters: 10mm up to 400mm

- blank & notching or for bigger diameters: 400mm up to 850mm

- laser cutting mainly used for small batched and prototypes

For the production of the lamination stacks we offer the assembly of the laminations by interlocking, riveting or welding. Your requirements and needs for the product as well as the further processing of the parts have a deciding influence on the choice of the packaging method. Therefore, a detailed consultation with our team of experts is important.

Our laminations are produced with high-quality steel from 0.3 to 1mm thickness and steel or carbide tools. In our in-house tool shop, we can perform all revisions and maintenance of the tools within the shortest possible time. Depending on your product, we can build multi-row tools to achieve the best efficiency in production at very profitable prices.